From the start one thing was certain, I didn’t want a show car, but a GT to drive on a daily basis. Even if you had to do some modification more reliable and trouble-free technology should be integrated. The

2-liter The 2 liter FI engines rev up quickly on the highway in

the GT. With the one look at the tachometer I was frightened to see the

effects of 6200 revs/minute on the effort and the expenses of an engine

change. These sound effects

with can be endured only with a grim expression over a long period of

time. For sure the engine could have been revved even higher.

I also would like to drive faster, but anyone hearing the

tack-tack-tack announcing a failure of the rod bearings, can live

without it for the next 2 or 3 years.

Speeds beyond 180 km/hs (110 mph) are a bit nerve-racking and should

only be endured for a short time. But you can live with a reasonable

noise level and engine rpm’s at 160 to 170kph (100-105mph.

Practically it looked different. I ignored the

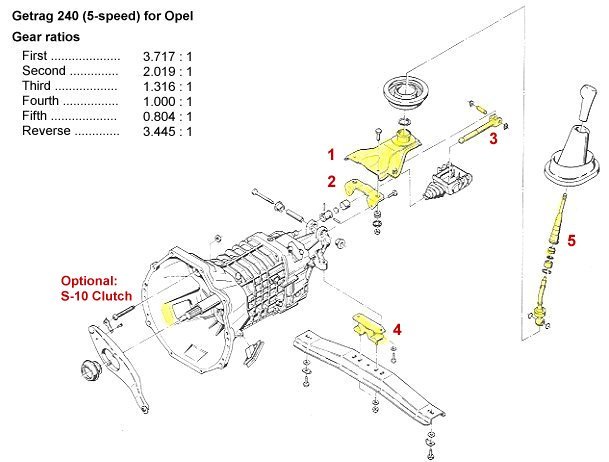

original optional Opel/ZF-transmission because of its high noise level.

I concentrated my search on one, the Getrag 240, with the fifth gear

.803 final drive ratio. Like many of you know, it’s not easy to find

this type. After some searching, I was lucky to buy a Getrag

240 from a Record E with 47,000 km (29,000 miles) for 700, - DM.($325

USD). The tranny looked rather huge, like it wouldn’t fit in the GT

transmission tunnel.

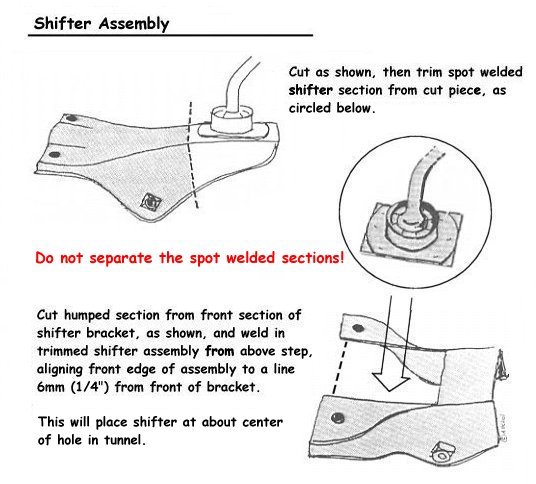

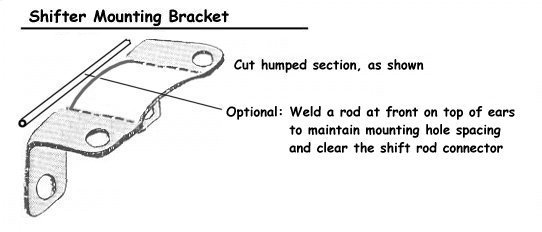

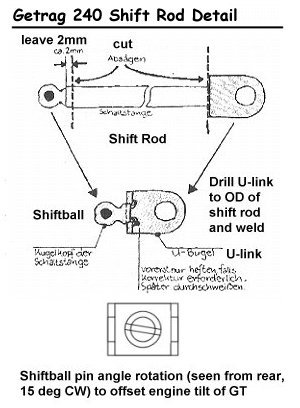

I did some research and concluded that, without

question, the gearshift extension would have to be shortened.

Additionally, I would have to bend the gearshift to fit exactly. I built

a mock-up of the original to test fit. See Fig. 1 I built a wooden plate and inserted 4 dowels to

mate to the bellhousing. The pivot point of the shifter plate is also

simulated with plywood and dowels.

Abb.2. A piece

of cardboard is also used to estimate the location of the shifter while

in the neutral position of the shift pattern. (fig.) 3). In addition, it

establishes the length of the travel for the 5-speed mechanism.

The Getrag mechanism 5-speed mechanism is different from the

original 4-speed shifter principle. It only has one cross-connecting

link, that leads from the front to the back of the body of the mechanism.

The gearshift lever is attached to the shift plate with a ball-joint and

connected with the shift linkage. This construction already leaves the

possibility of a precise shift pattern suspect. The rebuilt mechanism is in Figure 1.

Step 1 Step 2

Step 3 Step 4 Step 5

Step 6 Step 7

Step 8 Part II: Installation of the Transmission

Installing the gearbox

Now with a bit of serious thought:

Instead of the big extension you can also use three short extensions

together. Loosening of the bolts on the bottom is easy. After the

transmission is bolted on, the motor is easily lifted in front using a

jack with wood inserted to prevent damage to the oil pump cover. The pump is exposed and can easily be damaged. At this point

the engine is at a steep angle, and care should be taken not to strike

other parts of the engine compartment.

With injection engines the cold start-valve at the suction tube area is

a tight fit. Therefore, a helper must watch that the cold - start-valve

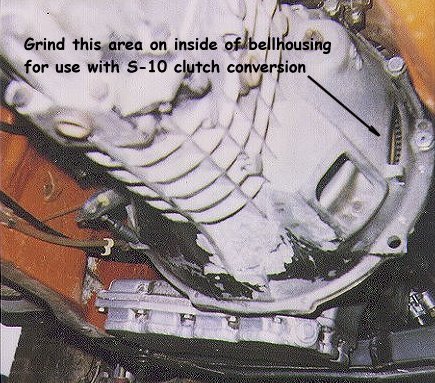

doesn’t hit the windshield wiper posts. With a carburated motor the Before

bolting the Getrag in place, you must install the original 4-speed

clutch release arm. The lever is identical, except in the mounting of

the clutch cable, the GT has a ball-piece, the Getrag, a threaded screw

and ball. An alternative is to swap the clutch cable. Then, the

comfortable adjusts slips however - possibility the clutch above in the

motor - area.

Now you can start to fit in the Getrag. With some feeling and something

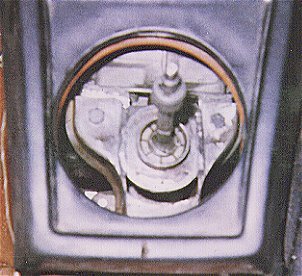

That works out jerk-in straight away. The completed gearshift-assembly (hold-angles

" B ") see part l, remains dismantled during installation.

After the installation of the transmission complete the installation of

the shift linkage. Now,

check the position of the shift pattern in the vehicle.

If it is incorrect it can be repositioned and corrected, see Part

l.

The wires for the reverse light switch must be extended, since switch on

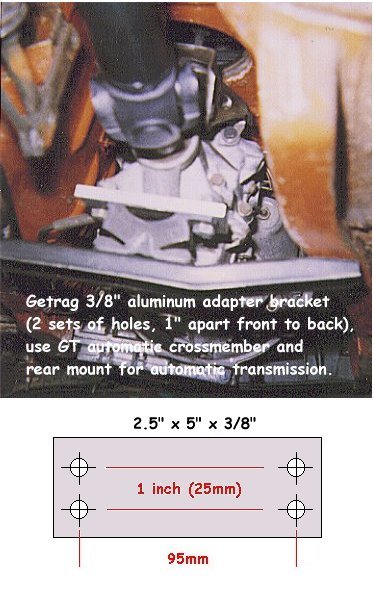

the other side of the transmission. Also the transmission cross-member

on the Getrag 240 sits 9 cm further to the rear than the original

cross-member. The rear transmission mount must be used from the Getrag,

This sheet metal strip was installed after being cut, bent in to a

vee-eight re-welded. When this cross-member was ready, it still appeared

the mechanism sat too low. Therefore, I put another 8 mm thick

aluminum-block between the cross-member and rubber. If not done, the

drive shaft would bend at too severe an angle. You can control the

height of the transmission based on a comparison measurement from the

stock-GT. Remove

material from the sheet metal edge of the gearshift hole Remove material until on the driving shaft with the

Original-GT approximately 120 mm, beim Five-speed approximately 117 mm,

tail-piece on the drive shaft has a larger diameter. The bolt-up of the

Getrag connection of the transmission cross-member takes place in the

holes for the for the automatic transmissions. Fig.,

The tail-shaft of the 5-speed transmission is larger at the rear than

the original manual transmission. It closely matches the Opel automatic

transmission tail-shaft. Unfortunately, the GT’s available automatic

transmission drive shaft doesn’t fit either.

It’s to short for the Getrag. Therefore, the Automatic drive

shaft must be lengthen and the flange mated for a U-joint. At a salvage

yard a drive shaft from an Ascona (1900) cost 30-40 DM ($12-15 USD). This

drive shaft must be properly shortened to the correct length and

re-welded. Here, do-it-yourself is absolutely prohibited. You can

improperly weld the seam and structurally alter the material that may

ultimately lead to failure of the drive shaft. For safety reasons, the

re-welds must be thoroughly inspected for hairline cracks.

Also the balancing can only be done on specialized equipment.

Balancing is no problem, if he has a fitting for an Opel drive shaft.

If this service is not available, you could go to one of the GT mail

order suppliers. There you get a drive shaft that has already been

shortened and re-balanced. Prices range from 200-300,-DM ($90-140 USD),

time of delivery approximately 2-3 weeks, they also do also do custom

orders. The use of the

automatic transmission drive shaft is somewhat less expensive. Speedometer-adjustment The

connection of the speedometer cable to the 5-speed transmission is no

problem, only the speedometer will register 40 km/h (25 mph) too slow.

This can be remedied by calling the VDO Factory. The branch office in

Hanover has been very cooperative and friendly in the past. Since

one something similar, particularly as GT-drivers, not at all more know,

I like to mention it. A test of relationship between the numbers of

rotation and the distance the whells rollof thethe rolling lenght

brollversuch first became through - led, i.e., a marked route became

departed and with help an on them/her/it Speedometer-wave of pretentious

gauge the register was determined. The register indicates the number of

turns the speedometer gear must make to register one kilometer. With my

car with 205/60 tires, original 3.44 rear axle and the 5-speed with a

blue pinion in the speedometer. The

register was W = 685. VDO can re-calibrate a speedometer, in principle

however, not this speedometer. That leaves for this reason Legislators

only one deviation of 4% Speedometers

- The

speedometer mechanism should not be lubricated by any means. It is already permanently lubricated, despite the fact that

it has a provision for lubrication. An excessive amount of lubricant on

the mechanism will completely ruin it.

|